New test laboratory for Surface Performance – move complete!

Surface Performance have just completed the move to our new testing laboratory premises in London.

The new testing laboratory will specialise in the inspection, R&D and testing of sports surfaces. The lab is fully equipped with a full suite of specialist equipment that has been supplied by our partner, Deltec Metaal.

We look forward to working from our new HQ and growing the laboratory testing aspect of our business.

Below are some photographs of the new facility….

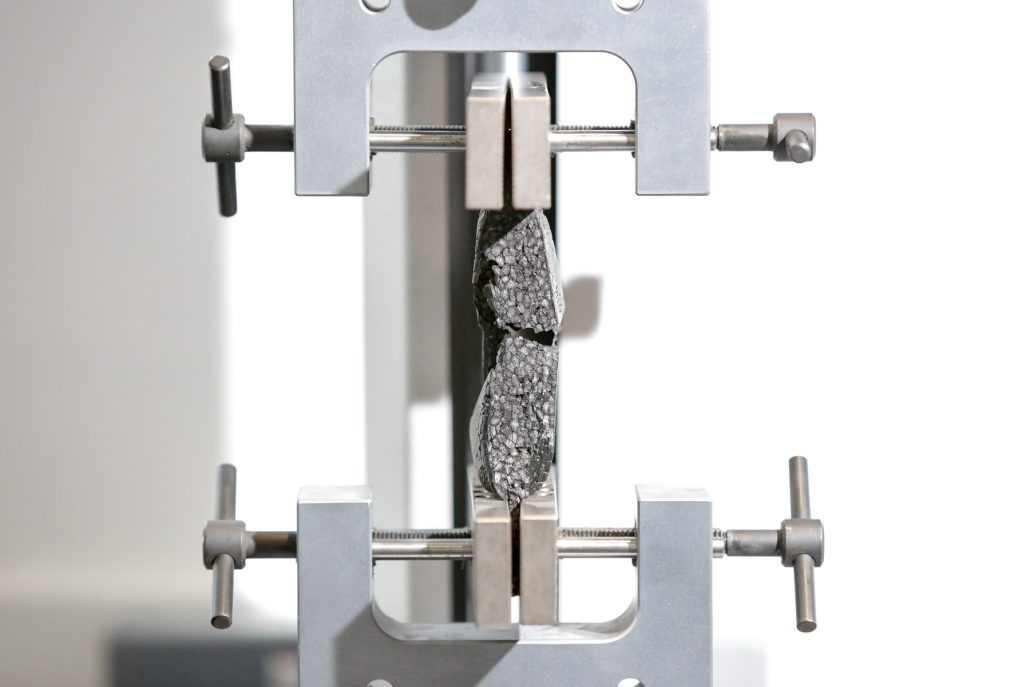

Tuft withdrawal test on artificial grass sample in Surface Performance Ltd new laboratory – BS ISO 4919:2012

Shockpad tensile strength testing at Surface Performance Ltd new test laboratory in London.BS ISO 4919:2012

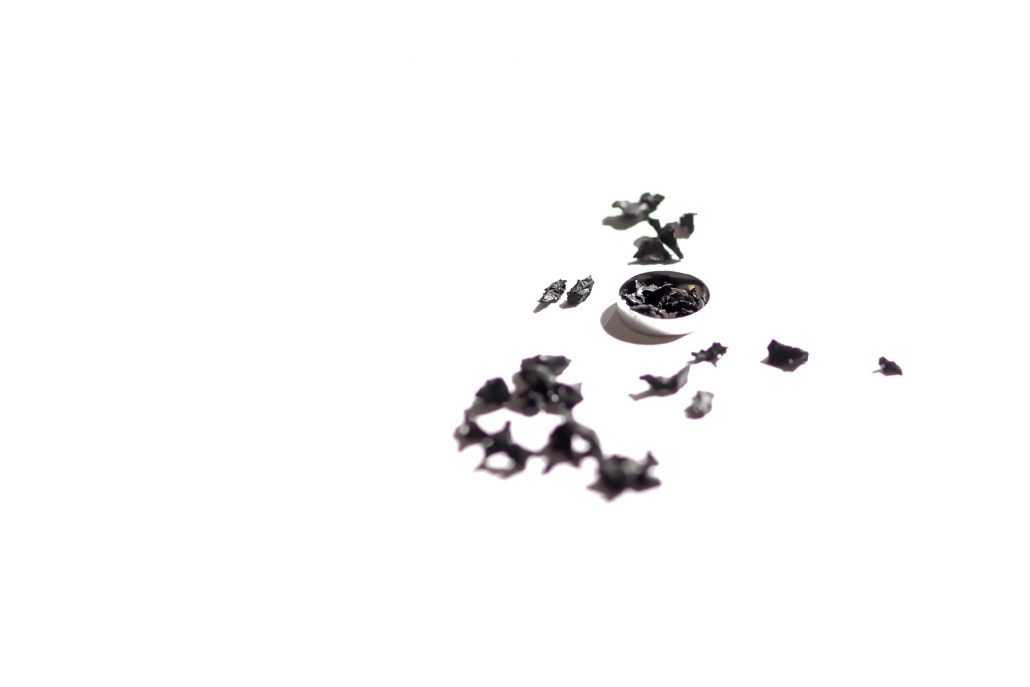

Testing of SBR rubber used in artificial 3G pitches

The Surface Performance Ltd testing laboratory is both temperature & humidity controlled making it a world leading facility.

DSC & TGA testing equipment used for FIFA identification testing of artificial grass.

UV testing of artificial grass samples carried out at the Surface Performance Ltd London testing laboratory.

The Lisport XL machine is used to simulate wear on artificial grass in the Surface Performance Ltd test laboratory.

The Lisport XL machine in action

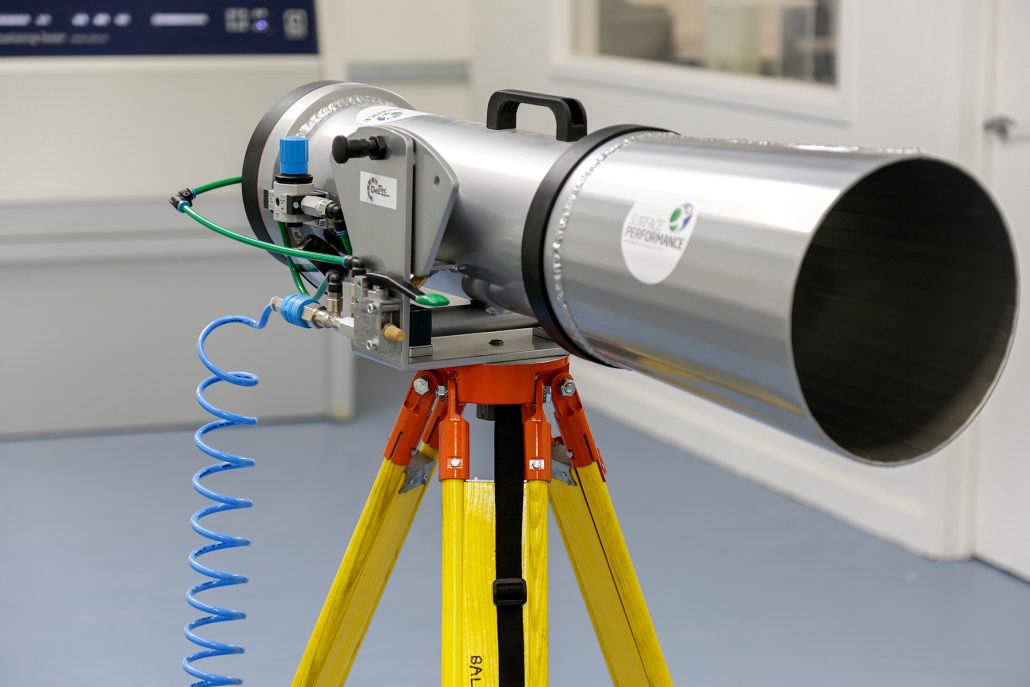

Ball cannon testing determines the pace of a ball before it impacts with the artificial grass and the speed loss after it rebounds from the surface

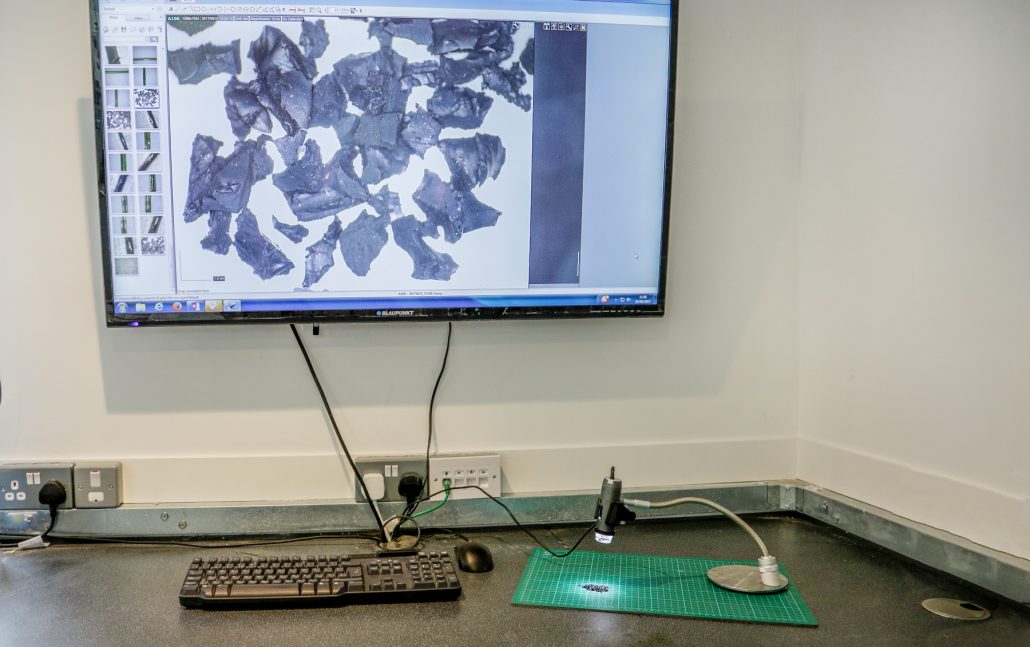

The particle size of sand & rubber are analysed in accordance with governing body requirements.

Both the larger & smaller testing rooms are environmentally controlled and accredited for testing activities by The United Kingdom Accreditation Service under ISO 17025.

The EN lisport machine is used to certify artificial grass products to EN standards. It is also the equipment used to simulate artificial wear when testing to the FIH Quality Programme

Rubber analysis carried out at the new Surface Performance laboratory